SAV: Establishing Itself in the Zhejiang Energy Storage Market with Technological Innovation and Quality Services

With the increasing maturity of energy storage system technology, the economic benefits and safety of industrial and commercial energy storage systems have been continuously optimized.

According to incomplete statistics from the industrial database of the Energy Storage Application Branch of the China Energy Storage Alliance (CESA), from January to June 2024, in terms of project filings alone, the total number of domestic industrial and commercial energy storage project filings exceeded 4,200, with an investment of over 24 billion yuan. Industry insiders predict that the industrial and commercial energy storage market will witness a significant quantitative growth in the second half of 2024 or the first half of 2025.

Zhejiang Province takes the lead in the filing of industrial and commercial energy storage projects. In September, the number of completed energy storage project filings reached 379, with a total investment of 6.043 billion yuan.

To date, SAV Digital Energy has successfully implemented over 300 projects, with a total installed capacity of over 200 MWh. Its customers cover a wide range of fields, including machinery manufacturing, electroplating, clothing, textiles, furniture and building materials, medical devices, semiconductors, agriculture, and biotechnology.

As a rising star in the energy storage industry, SAV has achieved self - research and production of its 3S core technologies, such as the Battery Management System (BMS), Power Conversion System (PCS), and Energy Management System (EMS) for its products.

The key for SAV to establish itself in the highly competitive Zhejiang energy storage market lies in its emphasis on research and development as well as technological investment.

SAV has a R & D team of over 100 people composed of senior energy storage engineers and technical experts, who are dedicated to the research and development of industrial and commercial energy storage technologies. At SAV, R & D personnel account for 35% of the total workforce, and R & D investment exceeds 7%. SAV is committed to innovative breakthroughs in energy storage technologies and promotes the industrialization and marketization of energy storage technologies.

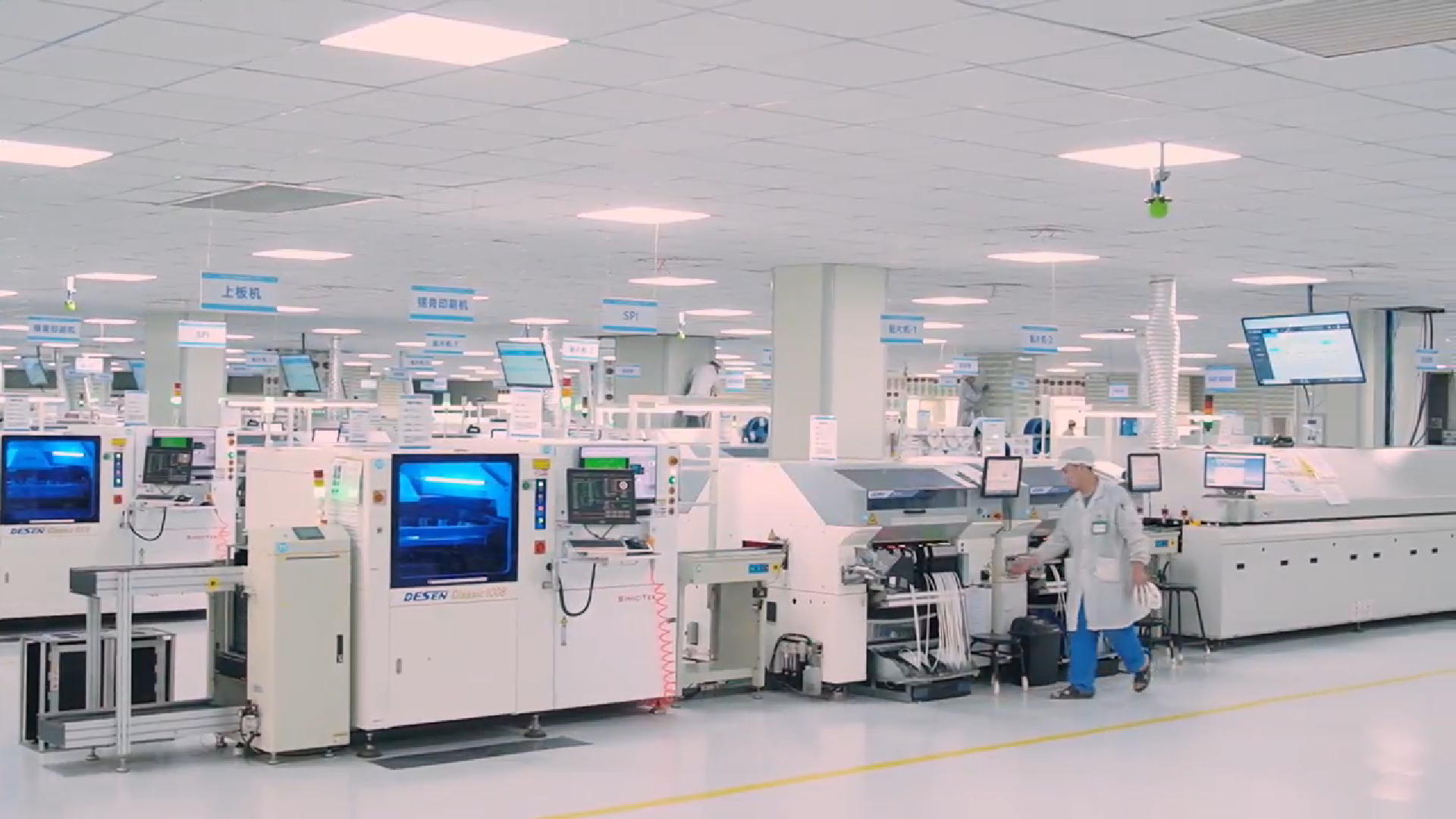

Entering SAV's SMT workshop, which is a crucial link in the production of electronic components for SAV's energy storage cabinet production line.

SAV adopts a fully enclosed dust - free cleanroom, equipped with an on - line constant temperature and humidity intelligent management system. The entire workshop's electrostatic ESD system features intelligent visual management, integrating monitoring and tracing. The MES traceability system for the entire workshop process has a coverage rate of 100%, enabling complete device - level traceability of products.

In terms of equipment, the solder paste printers, 3D SPI inspection equipment, fully automatic high - speed chip mounters, reflow soldering machines, and AOI automatic optical inspection equipment are all first - class brands. The mounting accuracy can reach ±0.05 mm, and the AOI resolution can reach 12 microns.

SAV not only pursues excellence in product quality and technology but also provides customized solutions. It meticulously tailors the most suitable energy management system solutions according to customers' electricity consumption needs and application scenarios, ensuring that customers can enjoy high - quality products and services.

SAV always prioritizes product quality and service quality, ensuring that customers can obtain the best product and service experience. It is precisely by virtue of its outstanding product quality and considerate services that SAV has rapidly risen in the industrial and commercial energy storage field, winning the trust and acclaim of numerous customers.