SAV's SMT Workshop: A Perfect Blend of Craftsmanship and Quality

Zhejiang SAV Digital Energy Technology Co., Ltd. has a mature and independent product R & D center. Its self - developed and self - manufactured commercial and industrial energy storage cabinets are carefully crafted energy storage products tailored to the pain points of users in the commercial and industrial fields. It not only has efficient energy storage and release capabilities but also an intelligent management system, which can provide stable and reliable power support for commercial and industrial users. And all of this is made possible by the exquisite craftsmanship and advanced technology in the SMT workshop.

Flexible, efficient, diverse, reliable, with active safety features, precise monitoring, energy distribution, and efficient utilization. Components include the Fire - fighting System (FSS), Energy Management System (EMS), Switch Box (containing the Battery Management System BMS), Power Conversion System (PCS), Air - conditioning System (HVAC), and Battery Module (PACK). These components work together to store and release electrical energy, stably and reliably supplying power to users.

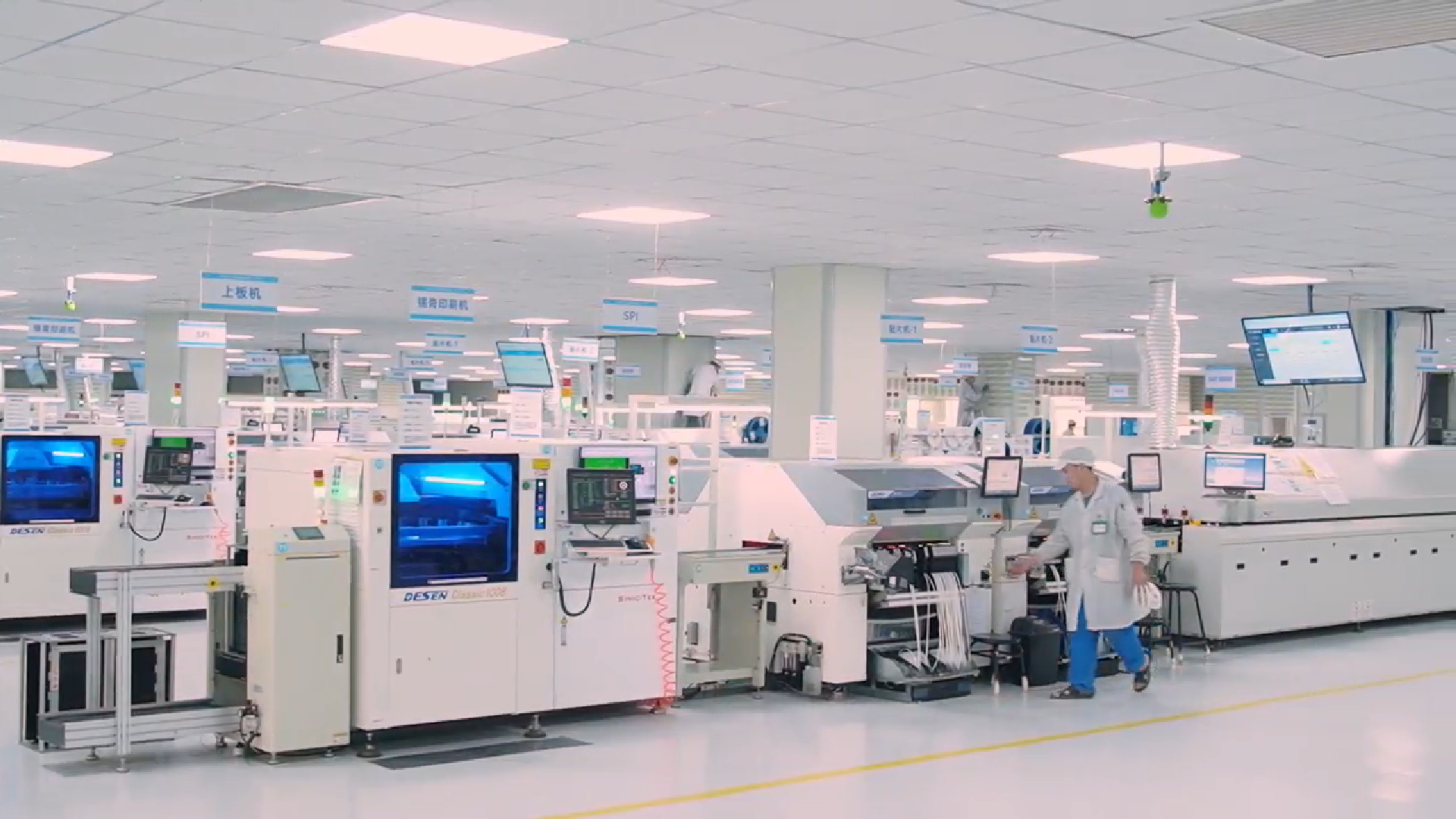

The SAV SMT workshop is a crucial link in the production of electronic components for SAV's energy storage cabinet production line. The Printed Circuit Boards (PCBs) produced in the SAV SMT workshop play a vital role in the energy storage cabinets. The SAV SMT workshop is equipped with fully automated SMT production lines, providing a solid guarantee for the efficient production of energy storage cabinets.

Tips: SMT, or Surface Mount Technology, precisely mounts electronic components onto Printed Circuit Boards (PCBs) to achieve circuit connection and functionality.

The SAV SMT workshop adopts a fully enclosed dust - free cleanroom to ensure the purity of the production environment. In the manufacturing of electronic components, dust and impurities can damage the components, affecting product performance and reliability. Therefore, the dust - free cleanroom provides a basic guarantee for high - quality production.

The SAV SMT workshop is equipped with an on - line constant temperature and humidity intelligent management system, which keeps the temperature and humidity in the workshop at the optimal level. This is crucial for the mounting and soldering of electronic components. Stable environmental conditions can improve production accuracy and quality.

The entire workshop's Electrostatic Discharge (ESD) system effectively prevents electrostatic damage to electronic components. Electrostatic discharge can cause component damage, performance degradation, or even complete failure. With the protection of the ESD system, the safety and reliability of the production process are ensured.

Intelligent visual management makes the production process more efficient and transparent. Managers can use visual displays to understand real - time information such as production progress and quality status, promptly identify problems, and take measures to solve them.

In terms of equipment, the solder paste printers, 3D SPI inspection equipment, fully automatic high - speed chip mounters, reflow soldering machines, and AOI automatic optical inspection equipment are all top - brand products at home and abroad. These advanced devices not only improve production efficiency but also ensure that the mounting accuracy can reach ±0.05 mm and the AOI resolution can reach 12 microns. Such high precision and resolution can quickly and accurately detect product defects, ensuring that every energy storage cabinet leaving the factory meets high - quality standards and further enhancing product quality.

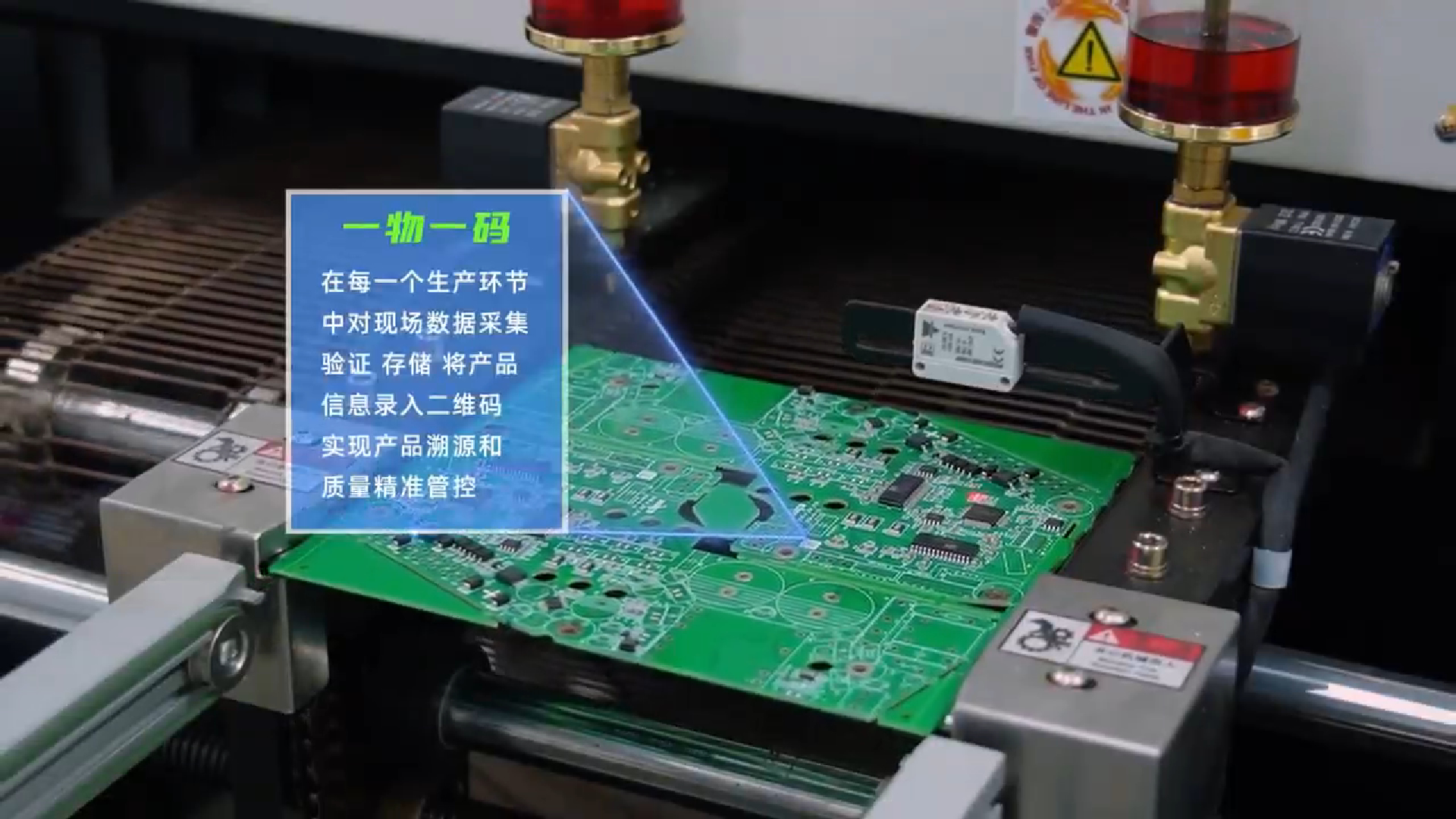

The "one product, one code" system collects, verifies, and stores on - site data at every production stage. Product information is encoded into QR codes, enabling product traceability and precise quality control. Integrating the production process with quality control and automated monitoring and tracing is another highlight of the SAV SMT workshop. The MES traceability system for the entire workshop process reaches 100%, and products can be traced at the device level. This means that every production link is recorded, and in case of problems, it is possible to quickly trace back to the source for effective quality control.

The SAV SMT workshop, with its advanced technology, strict quality control, and efficient management, provides a solid quality guarantee for the overall production of SAV commercial and industrial energy storage cabinets. Every link in this workshop pursues perfection, and every product embodies the wisdom and hard work of SAV employees. It is believed that in the future, the SAV SMT workshop will continue to leverage its intelligent advantages to provide customers with more high - quality and reliable energy storage products.